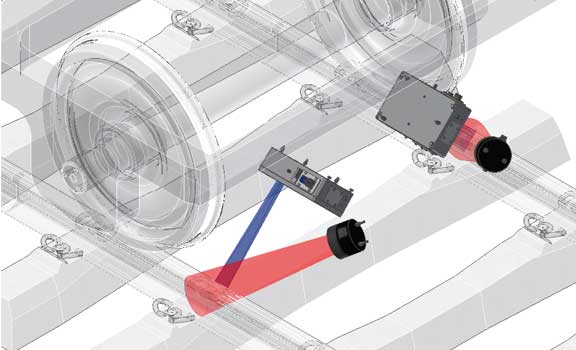

HeadCheck has been specially developed for the detailed automatic inspection of the rail running edges. At a speed of up to 180 km/h the system checks the edges for fine Head Checks and assigns them different states.

Recording

The recording takes place independent of the speed with monochrome, high-resolution, digital high-speed line scan cameras that are protected against environmental influences and damage in robust protective cases. The photograph is triggered controlled along the optical path length by means of an incremental position encoder linked to the wheels. High-quality macro lenses are used for control that is as detailed as possible. Special headlights ensure optimum illumination and highlighting of the slightest faulty structures.

Evaluation / Documentation

The resulting images are evaluated online by means of ultra-modern image processing algorithms. The fault patterns are classified automatically and the results are provided in a fault protocol immediately after inspecting the rails, archived in a database or forwarded to superordinated systems.

Résumé

The system includes the following features:

- High-resolution graphical data for the detailed analysis of the inspection area recorded.

- Easy operation; intuitively controllable user interface.

- Modular concept.

- Low maintenance expenditure.

- Proven suitability for railway vehicles.

- Easy integration thanks to small space requirements.

- Open system; thereby easy adaption to country-specific database systems or central data acquisition on the vehicles.

HeadCheck

HeadCheck