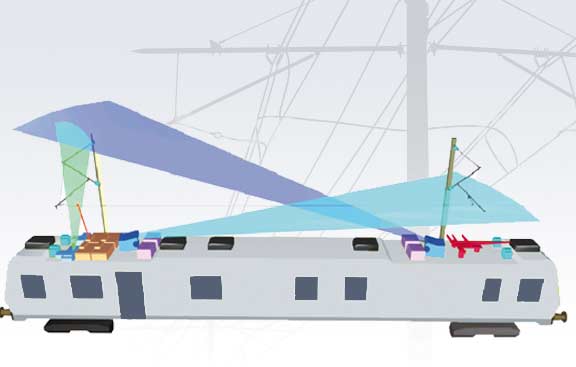

CatenaryCheck is an automatic inspection system, which inspects the catenary and catenary cross span at high speed. In view of the ever increasing railway line occupancy it is imperative that an objective status of the inspected railway line be available to the user with the most modern technology, high quality and safety in the shortest time. With the aid of pioneering sensors and the most modern image processing technologies CatenaryCheck ensures that the contact wire inspection is fast, safe and reliable.

Recording catenary

The sensor system is installed in device modules suitable for railway vehicles on the roof of the measuring vehicle on both sides of the contact wire. Each sensor contains a high-energy, laser-based illumination unit. At a speed of more than 120 km/h, digital line scan cameras continuously record graphical data of the entire catenary, store this data and make it available for the later evaluation.

Recording catenary cross span

A special recording technique enables the catenary cross span to be recorded by means of digital line scan cameras from both sides at a speed of up to 120 km/h. The process ensures that optimal image quality is provided for the subsequent processing steps, which makes even the finest details of the catenary cross section visible.

Evaluation / Documentation

The graphical data recorded during the inspection run is evaluated offline. The recorded graphical data is compared automatically with the previously stored reference values assigned via the track chainage. Differences between the actual status and reference status are stored in the form of a database. Special software analyses the differences and determines the degree of severity of the fault. The results are stored in a database and can thus be made available to the superordinated systems for further processing.

CatenaryCheck

CatenaryCheck