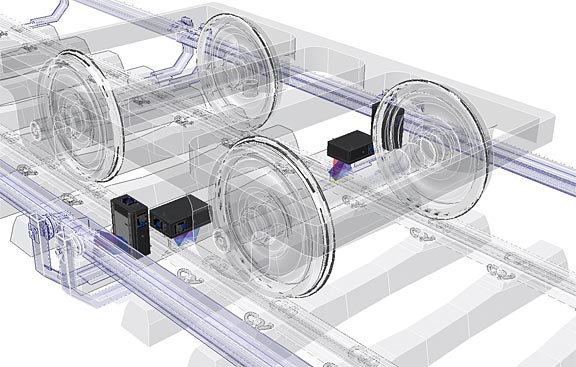

3rdRailPositionCheck is an automatic real-time measuring system to determine the position of contact rails on tracks. Measurement reports are generated as a result that show the deviations of the contact rail's position from the set position and generate an error message if tolerances are exceeded. In the basic version, the system works up to a speed of 130 km/h at a measurement interval of 10 cm. Higher speeds and shorter intervals are possible depending on the requirements.

Principle

The measuring system is based on the split-beam method and in each case consists of a line laser and a camera. A laser line projected onto the rail is recorded by means of a special digital camera. Powerful computers automatically evaluate the image data and generate the reference points necessary for the relevant position. Using these reference points, which are generated by four sensor units, the position of the third rail is calculated relative to the side rail.

Summary

The system is characterised by the following features:

- High measuring speed at a short measuring distance

- Resolution of <1mm

- High measuring certainty

- Modular design

- Low maintenance

- Easily integrated since low space requirements both below and in the vehicle

- Open system; thus easily adapted to specific national database systems and/or central data acquisition in the vehicles

3rdRailPositionCheck

3rdRailPositionCheck